The press brake finally in place alongside its two 24" Di-Acro buddies. The flash on the camera accentuates the slightest rust on a tool, but this is only surface rust that comes off with a Scotch-Brite finishing wheel.

Over the years of refining which tools I keep in the shop, perhaps nothing has irritated me more than the Chinese 3-in-1 press brake/shear/roller that I bought twenty years ago. It was okay for small work in thin, soft materials, but simply didn't step up to the demands of some of the materials used in WWII aircraft radios that I work on. Thanks to a couple of home shop club members, I was able to acquire a nice Di-Acro finger brake, and later a Di-Acro shear, both with a 24" capacity. They have more than carried their considerable weight in the majority of tasks I need them to do, but there is one material common in WWII radios that is beyond even their capability, and that is 16 gauge 316 stainless steel. It is simply too tough for unassisted working of the material. I tried a number of work-arounds with the 3-in-1, but none of them were satisfactory. Then I discovered that Di-Acro had manufactured a 24" capacity press brake through about 1985, capable of eight tons of force, so I began searching for one in reasonable shape. That's when I found that the available machines had often been abused by the sheet metal trade, with broken and missing pieces, repair welds, and a general scruffy, uncared for look - often hidden under new paint. Since they had not been manufactured for 30 years, the ones I had a chance to inspect just didn't fill the bill, or were over my budget. Finally, I located a decent one near Elmira NY that also came with some 24" dies, and picked it up in January 2016.

Before using it, I had to dismantle the sliding parts of the ram to clean and lube the bearing surfaces, as well as paint the ram because of some bad flaking and yellowing of the original almond tinted paint that is visible in the photo above (along with some rather gruesome decals warning not to put your finger in the opening whilst pressing...they had to go...) I'm going to delay a complete repaint job until after I have some fun with the machine.

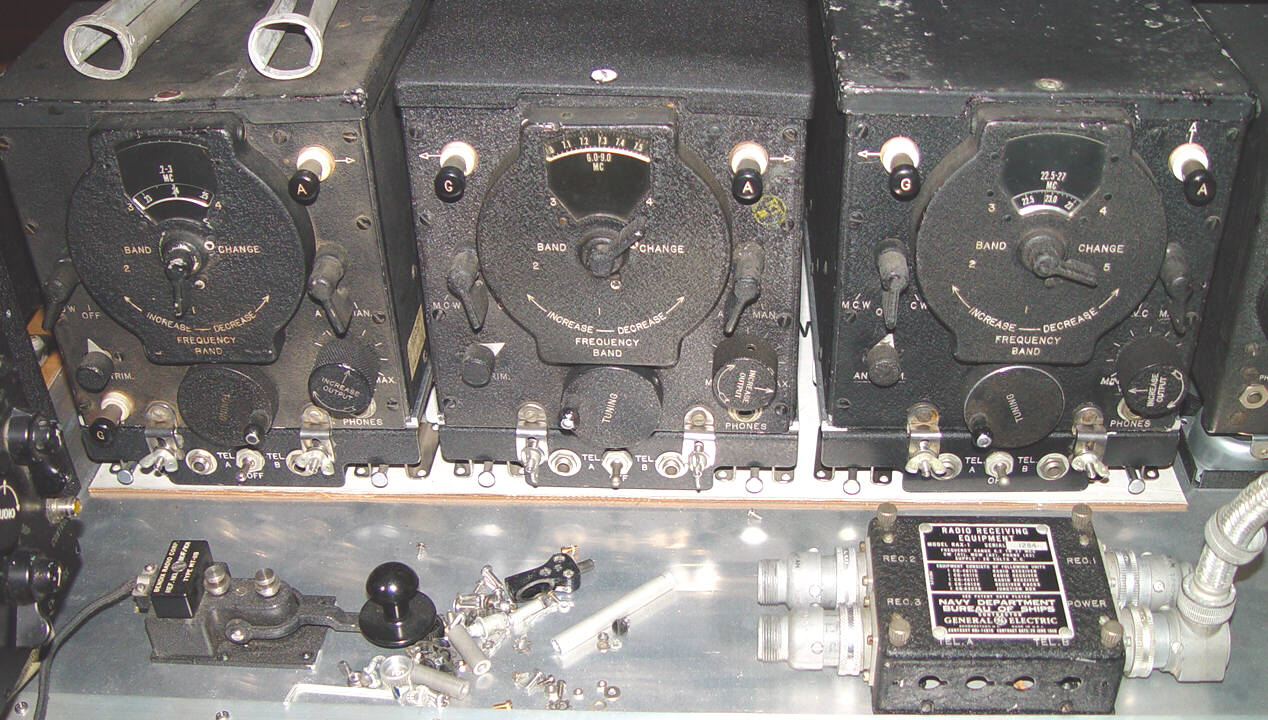

I finally found a few minutes to try it out in fabricating my old nemesis - some Navy RAX-1 aircraft radio receiver mounts - which are 16 gauge 316 stainless steel and defied every attempt to bend them accurately with any other tool in the shop. The receivers are shown below:

Four easy one hand pulls of the lever, and voila! It was so easy, it was strangely infuriating! When I think of all the attempts I went through to make these four simple bends, I wonder why I didn't look for one of the 16-24 brakes ages ago! The fact that Di-Acro designed the brake to use pieces of the same dies which are used on much larger presses was a big plus, and I've picked up a bunch of shorter dies on ebay at reasonable prices for making boxes and the like. I acquired two offset dies that are perfect for pressing deep and/or narrow channel like the radio mount (photo below).

Now, it should be understood that I don't have any pretentions of being a seasoned sheet metal expert, so this has been an educational experience for me. One thing I learned in the process was that trying to keep all four bends absolutely parallel (so that the resulting chair wouldn't rock), and keeping the apex of the male die precisely located relative to the reference end of the workpiece for each bend, takes careful work - even more so on a short 2" test piece like this one. There is evidently a slightly variable drag on the bottom (female) vee die edges as you first begin the bend, even with polishing, and it can apparently cock the workpiece a few thou in the process of air bending it. I tried some of the urethane die film made specifically for female dies, and it helped but wasn't perfect. I need to initially make 16 of these things for four radio receivers...one of the mounts go at the four corners of each receiver rack, so for the production run it seems prudent to make a longer workpiece and cut them off in the bandsaw, like refrigerator cookies. A movement of .005" on one end or the other of a 8" workpiece (+3/8" extra to accommodate the bandsaw blade cutting waste and allow four chairs to be made) is a lot less angular movement than with a 2" piece. That length workpiece in this tough stainless calculates at about 4 tons required to bend a right angle with the 1/2" opening female die, so it's well within the published 8 ton capacity. Another thing I discovered in the bending process was a property of metal, particularly stainless, called springback - the tendency of a pressing to return to a flatter angle when pressure is released. The Di-Acro is thoughtfully made to accommodate this - one hand on the right hand coarse position lever and the left hand on the high pressure lever allows ratcheting up the pressure in one tooth increments until a right angle is achieved.

More on the radios that these mounts will ultimately support can be seen here.