WWII Aircraft Antenna Insulators

IN-81 and IN-82 Standoff Insulators

The insulators below were mounted on bulkheads, struts, and other surfaces to provide support for the antenna lead-in between

the fuselage feed-through insulator and the transmitter or antenna relay. The IN-81 is 1.25" in diameter and 1.5" long, while the longer IN-82 is 1.25"

in diameter and 3" long. The hole through the insulator is not used for the wire itself, but for lacing cord to hold

the wire in the saddle on the end. Each type is held onto its mounting surface by a single #10-24 screw.

View of standoff insulators IN-81 and IN-82

********************************************************

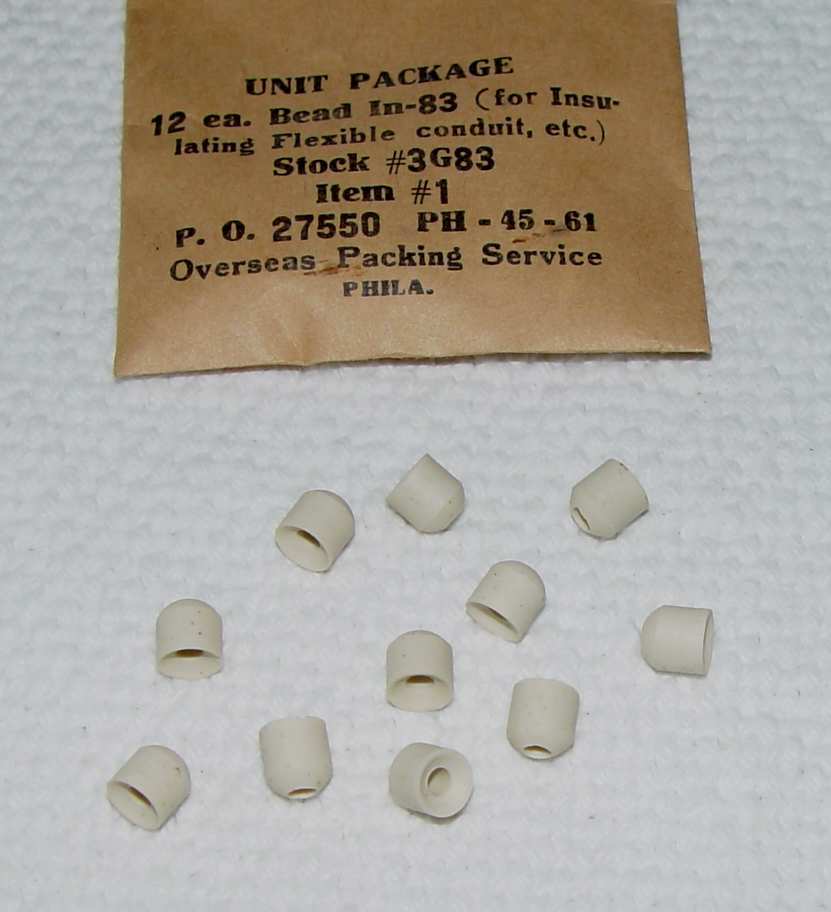

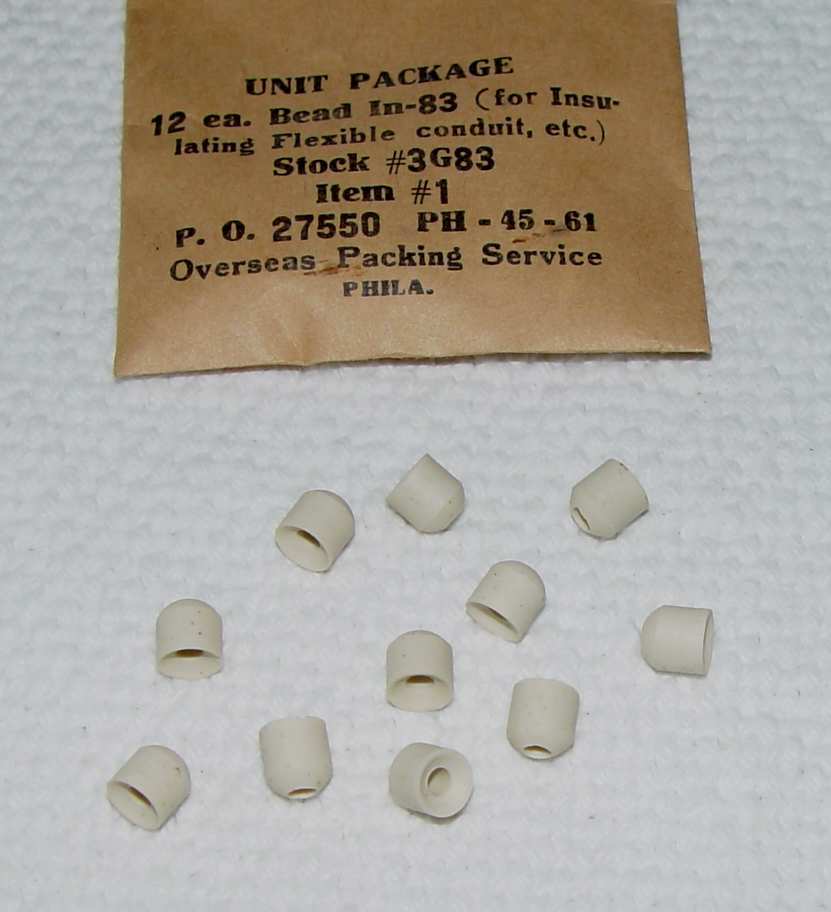

IN-83 Insulating Beads

Because of the potential for RF burns to operating personnel, some method had to be devised to insulate the antenna lead for

higher power liason transmitters that might operate in the interior of the aircraft. That problem was solved in two ways - first by using

spark plug wire (the Navy was partial to this approach), but more often through the use of ceramic beads strung on solid wire, shown below.

IN-83 is a Signal Corps designation, and is 5/16" in diameter, 48 beads per foot, which is about 1/4" long nested in the next bead.

The hole through the center accommodates up to #8 AWG wire, though it was normally used with smaller diameter wire.

The practice of using the beads was only for safety reasons, so although it was common practice in the 1930s with lower power

transmitters like the SCR-183 series, it was discontinued fairly early in the war by both Services for anything other than the

higher power liaison transmitters. The ARC-5 manual specifically mentions no need to use them. Still, they look neat and do

no harm unless they get damp with salt air or dirty enough to arc over.

The Navy had their own version of the antenna beads that had the number NAF 212989-3 (the suffix denotes the size). They were the

same size as the IN-83. Both Services actually had a variety of sizes for different diameter wire, but these are the most common

in the manuals.

Package of IN-83 beads, sometimes called fish spine insulators because of the way they fit together

********************************************************

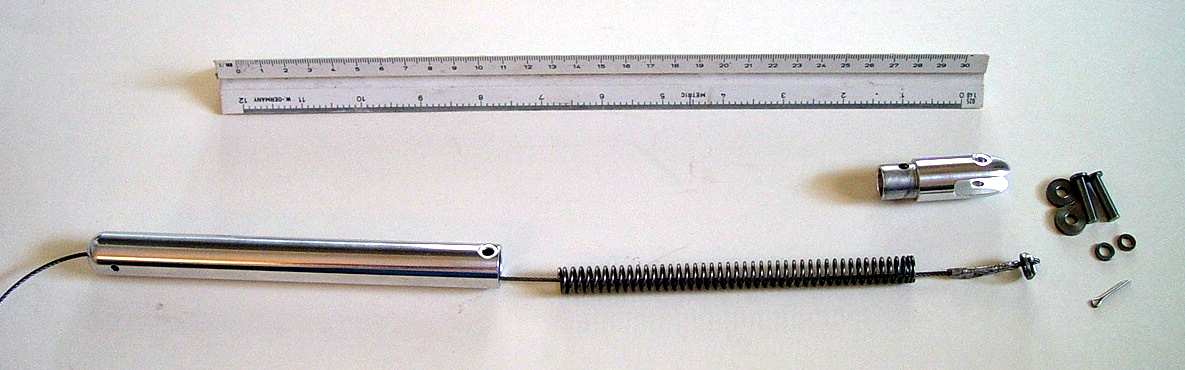

Tension units

Part and parcel of the design of a long wire aircraft antenna is the need to have a tension unit of some sort. The tension in a standard

18 guage Copperweld antenna is nsormally set to 15 pounds in the middle of its range. Below is an example of one I made for the Enola Gay,

based on original Boeing drawings, which can be viewed here.

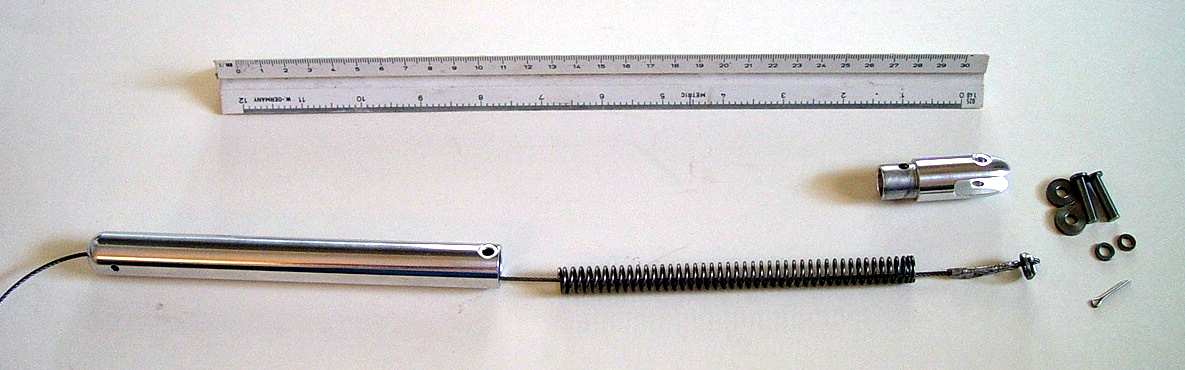

Overall assembly of a B-29 antenna tensioning unit for the command antenna.

Exploded view of the tensioner.

Adjusting the tension to 15 pounds. The scale is located at the other end of the antenna.

The Navy took a different approach to their tension units, using rubber to avoid salt spray binding problems encountered with sleeve type or open spring

units favored by the USAAF, like the example above. Photos of these tensioners are shown below. They were black rubber underneat a coat of aluminum

paint - there is some overspray on the end hooks. At this point 75 years kater, the aluminum paint rubs off very easily.

These longer tensioners were assigned the designation of NAF 213089-1, and had a long application lifetime, being mentioned as the standard Navy aircraft antenna

tension unit in both the 20 August 1936 NRL Radio Materiel School and December 1942 Naval Air Technical Center training volumes. They are ~10" from

end to end of the hooks embedded in each end. Outside diameter is about .550" (9/16" nominal), but of course that diameter reduces slightly when tensioned.

These short Telephonics products don't have an NAF number on their exterior, and I have not been able to find a reference for where they were used.

They are ~5-3/8" from end to end of the hooks embedded in each end. The untensioned outside diameter is ~.550", like the longer ones above.

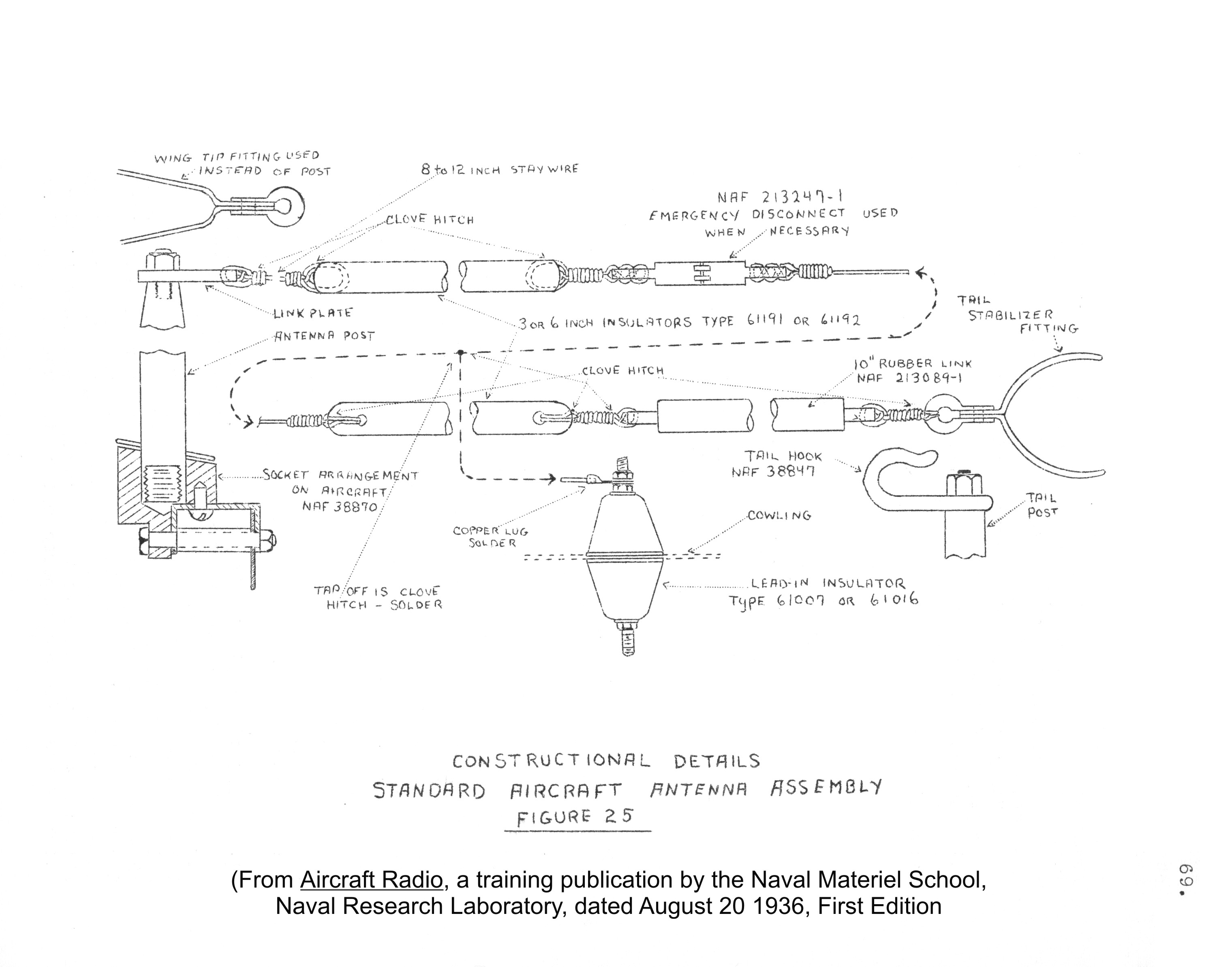

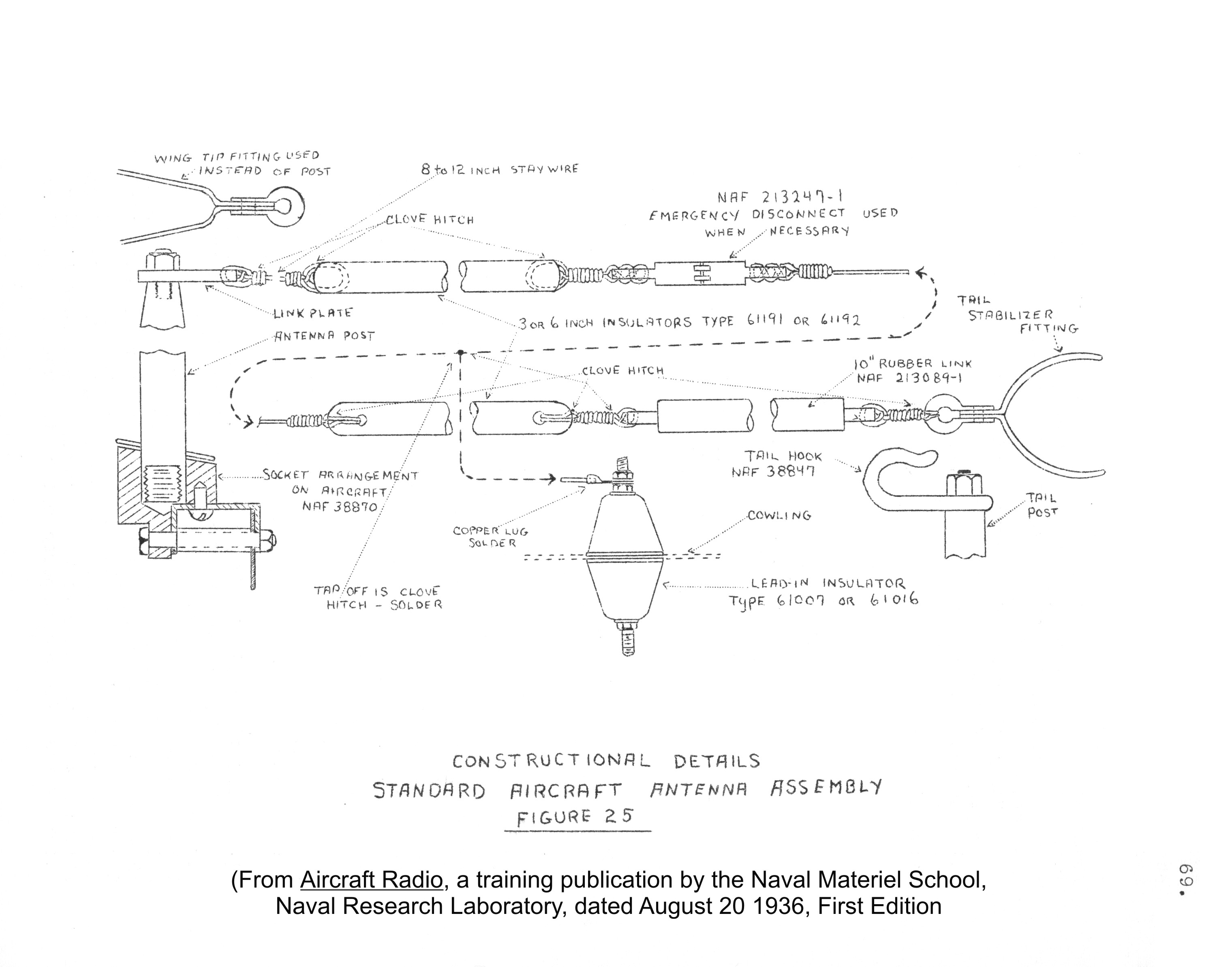

Below is a page from the 1936 training manual showing the breakdown of a typical antenna installation:

Return to Documents page