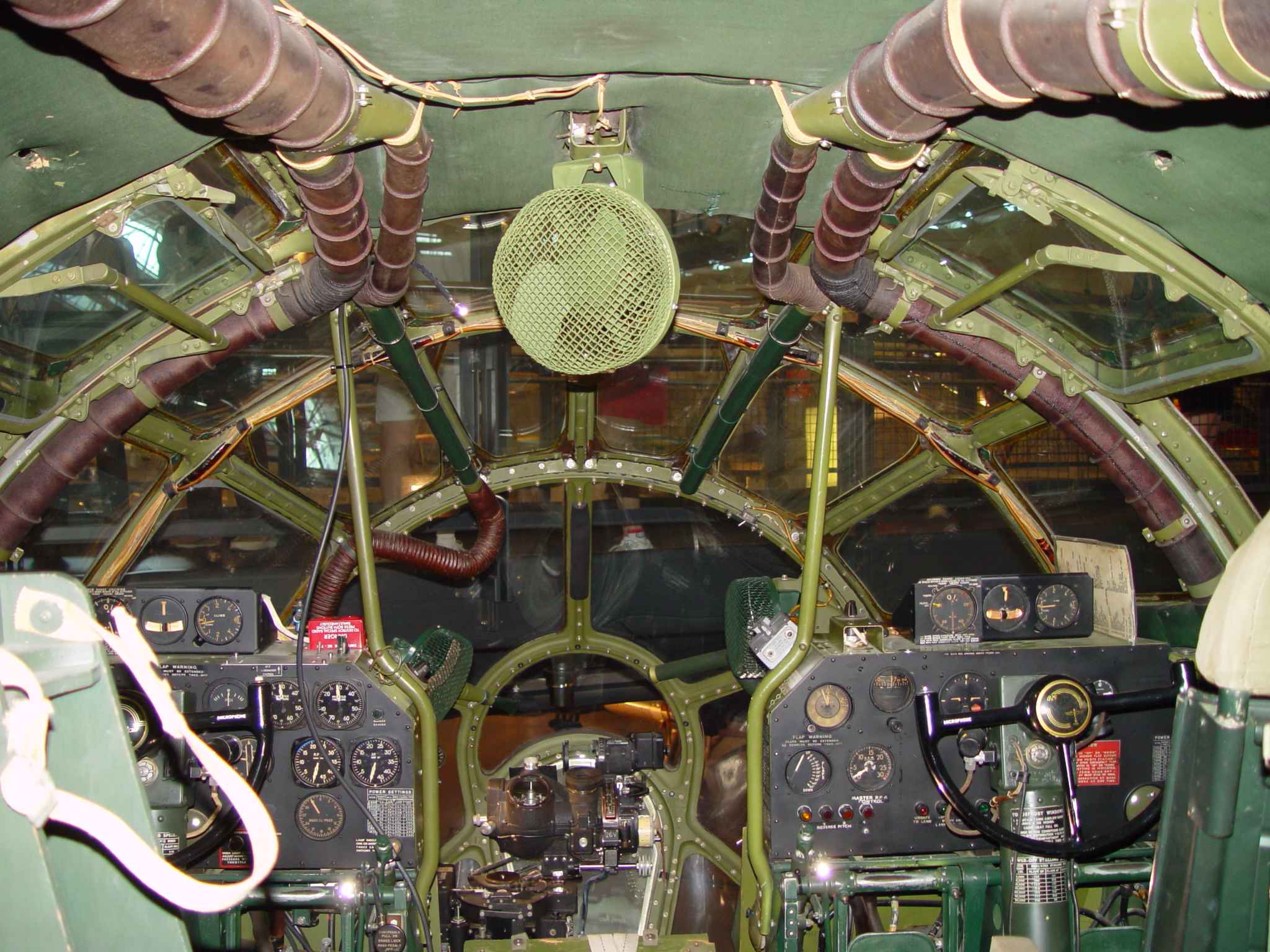

One of the oddball characteristics of the AAFRadio "flight deck" has been the addition of totally whimsical peripheral devices that have nothing intrinsically to do with the radios. They simply provide some ambiance. For almost five years now, I have been bumping my head on pieces of a restored cockpit fan hanging in the shop, victims of my atrocious painting methods. One of the reasons they have been hanging around for so long is that the fan, an ebay purchase, didn't have the proper mount that came with it in a B-29. There were three of these fans in each aircraft - two for the bombardier, who was the most affected during the sometimes interminable warmup and taxi sequence prior to takeoff. On Tinian,the heat from the sun was brutal, and the bombardier sat in a transparent cage at the front of the aircraft without a window to open for air. The only other fan was suspended between the pilot and copilot, shown below. Prior to the B-29, most of the windows in a large aircraft could be opened in hot climates, apparently obviating the need for a fan, but the B-29 was a pressurized aircraft, and as a result there was an air distibution system that delivered (heated) pressurized air throughout the airframe (the brown phenolic tubes strapped to the ceiling in the photo below). Fine above 10,000 feet, but on a hot tarmac it apparently left something to be desired...thus the installation of the first flight crew fans (but only for those under the Plexiglas ceiling in the cockpit.) Other aircraft had fans for windshield defrosting of course, but they were smaller and not very useful for cooling personnel.

I had previously renewed the Glyptal coating on the rotor windings and replaced the bearings in the fan motor, which is actually significantly overpowered for an eight inch two blade fan. It is a fairly standard WWII DC motor used for driving the windshield wipers in an aircraft, and that takes a fair amount of power. The rating on the motor says 1/8 horsepower at 6,000 RPM, 75°C temperature rise (too hot to touch!) Reflecting the low load, it doesn't get that hot in actual use. Once everything was done in the motor and all the parts painted, it was time to get busy with some fabrication. The acquisition of a decent 8 ton press brake last year finally permitted me to consider making the 1/8" steel strap hanger to match the original.

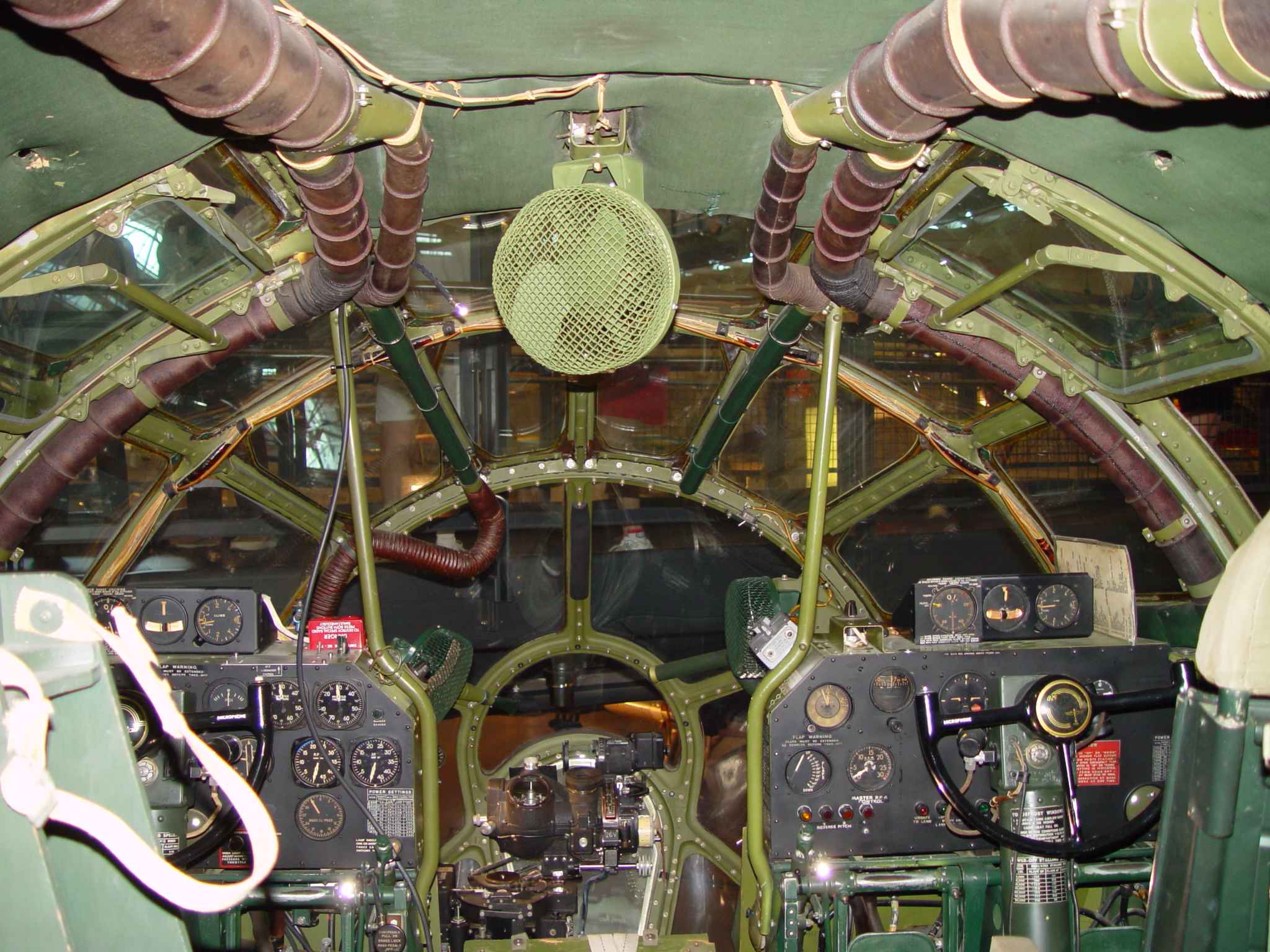

Naturally, the U-shaped mounting strap wasn't the only thing required. There is a platform attached to the airframe that provides a solid base, and using a phenolic washer, the fan could then be rotated 360 degrees to put its air wherever it was needed at the time. Couple that with the need for a convenient 28 volt power switch to turn the fan on and off, and the requirements resulted in this contraption below.

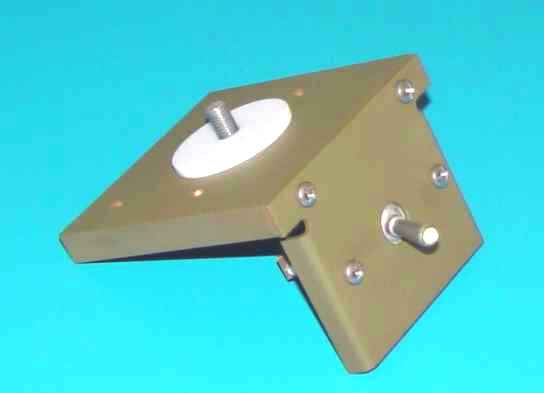

Finally, below is the complete assembly mounted on the left side of the AN/ARC-5 rack in the flight deck.