Typical roller inductor window shinkage problem is shown above.

The question of making new roller inductor windows for the command transmitters comes up every now and then, given that typical storage conditions for these sets was not generally conducive to stability or long life for the plastic. Looking through my collection of windows, I'm not even sure that the same kind of plastic was used over the years and models of this transmitter. A couple of them have a faint smell of acetic acid, suggesting cellulose acetate, while others have no discernable odor - just shrinkage suggesting "doll's disease". Of this latter type of plastic, Dr. Barry Ornitz of Eastman Kodak fame wrote, "The problem you are seeing is the leaching out of plasticizer from polyvinyl chloride or polyvinyl acetate items." Regardless of the type, the bad news is that there was no recourse to simply outright replacement.

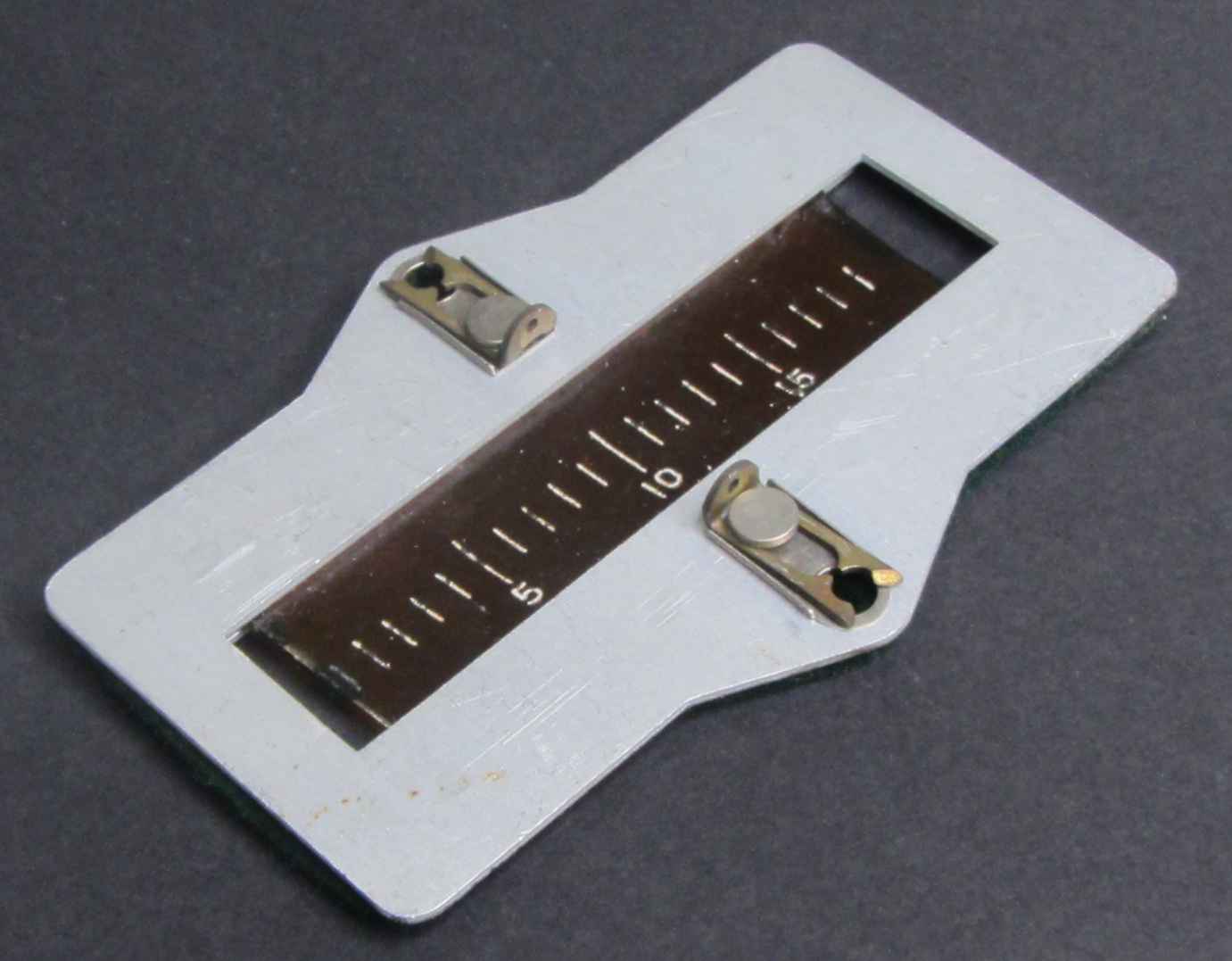

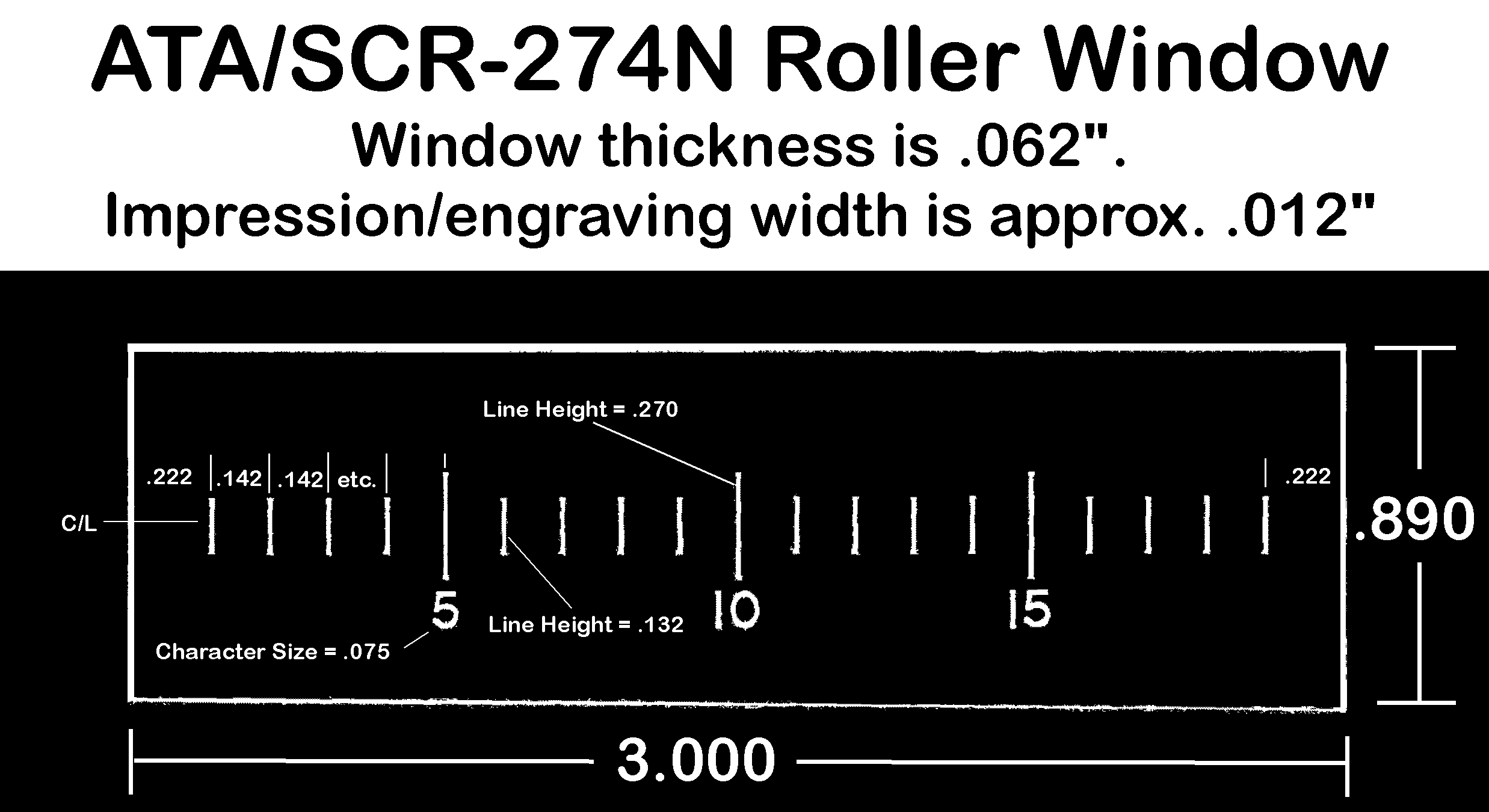

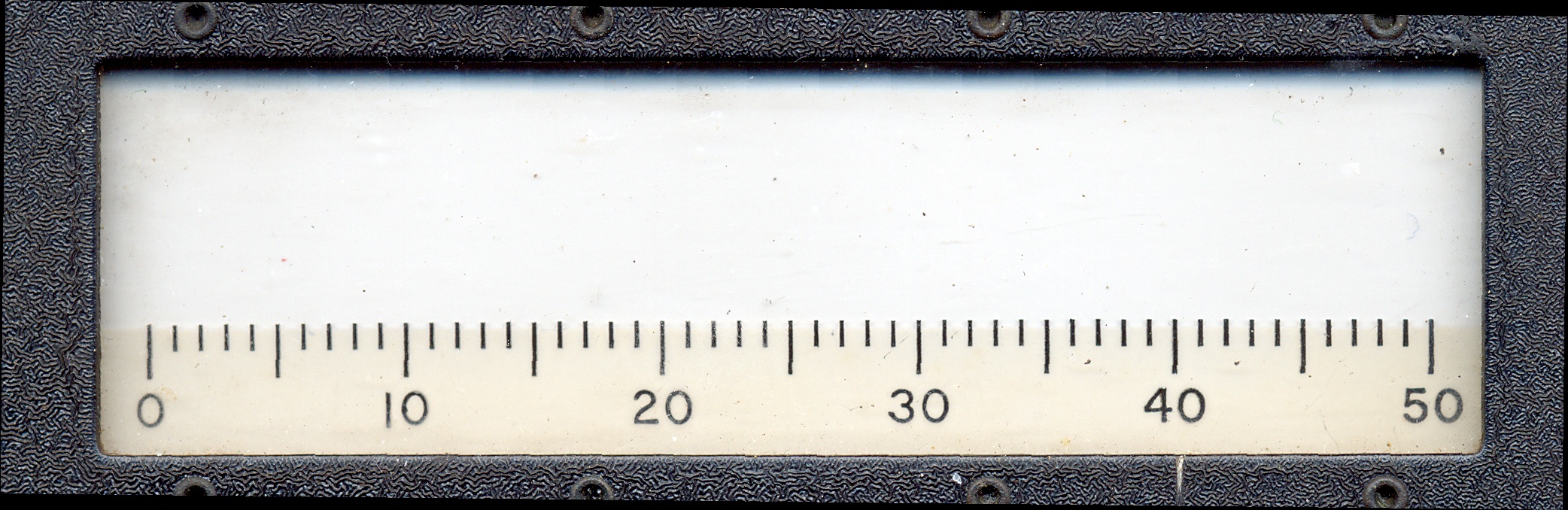

For those who might be inclined to try their hand at fabricating Lexan or Plexiglas substitutes, below are the dimensions for both the earlier command sets and the AN/ARC-5 transmitters. (Right click on images to get full size.)

On the earlier command sets, removing the old window for replacement is best done with a jeweler's screwdriver on the bent down tabs on one end. If you're careful, you can slide an Exacto blade under the green felt to break the glue bond and re-cement it after replacing the window. You may have to slip a blade under the cantilevered retention piece on each side to provide a tad bit more clearance to slip the window out and the new one in.

The dimensions for the lettering and marking lines can be scaled from this photo. The originals seem to be impressions made with typeset similar to that used in linotype equipment, but one could easily use an engraver. The impressions are made from the front of the window and are filled with white filler.

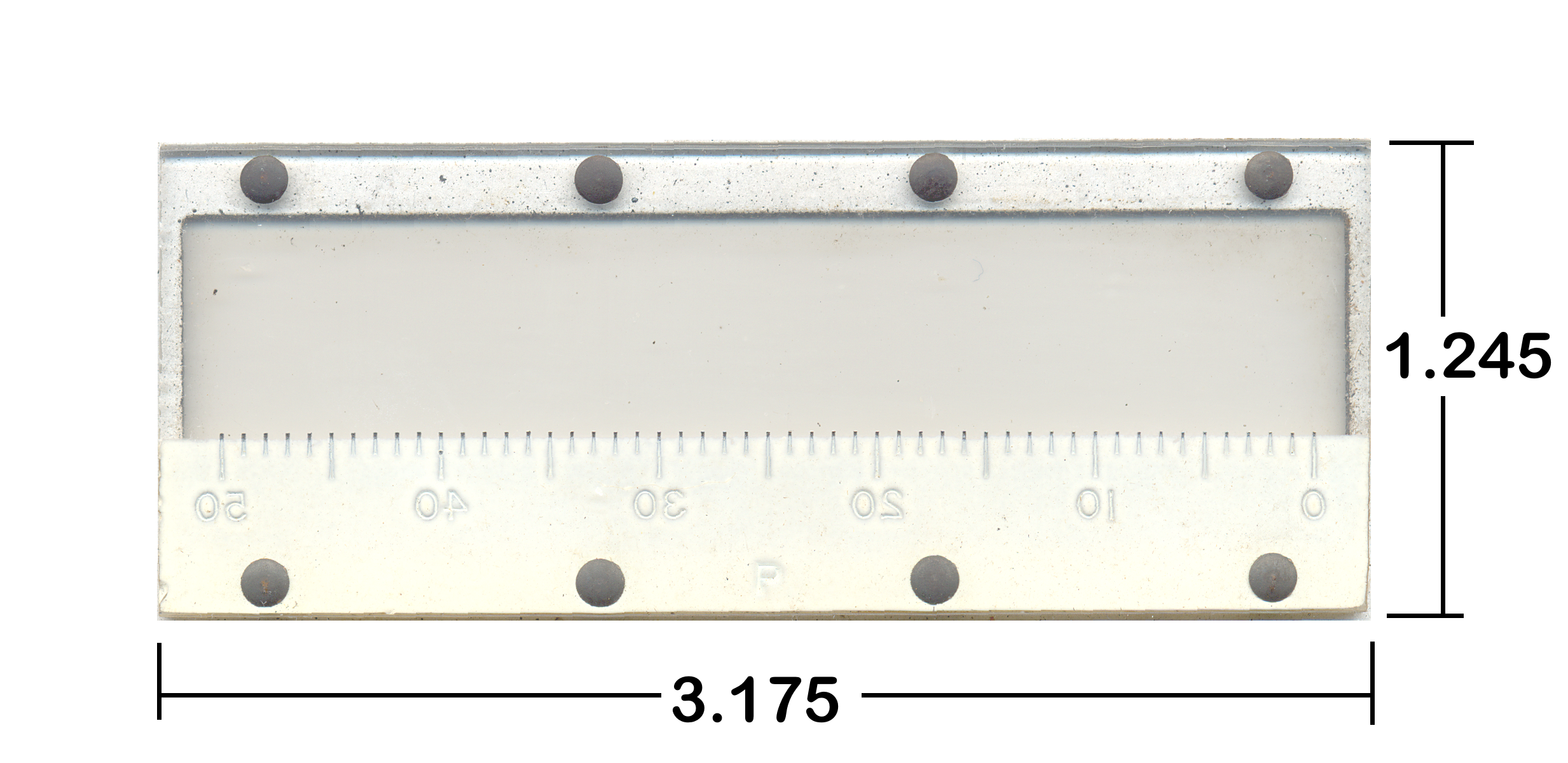

These are more of a challenge to fabricate. Typically, the storage damage is seen as cracks in the corners of the windows - not surprising, since they are held in place with eight 1/16" tubular rivets which put more pressure on the plastic. The clear plastic used is less prone to yellowing and distortion seen with the earlier material. In contrast to the older windows above, which are engraved from the front, the AN/ARC-5 tramsitter windows are engraved/impressed from the rear, then filled with black filler. After cleaning the excess, it appears that the top part of the window back was masked and a white paint or lacquer with a flattener was sprayed on the lower part, probably with something like an air brush. The coating is not very thick.

The plastic on this sample is slightly thicker at .070" based on a quick check with digital calipers, but I don't think I would worry about that small difference from a standard .062" thickness. For some strange reason, I wasn't quite willing to drill out the rivets on this pristine example to verify the thickness. To replace a damaged window, obviously you'll have to do that, as well as replacing the drilled-out rivets with new ones. These rivets are "set" from the front - probably in an attempt to distance the deforming pressure from the fragile plastic.

While neither of these window solutions is trivial, some experimentation with graphic solutions like water based decals and the like might be useful. If anyone comes up with any other alternatives, I'll be happy to append them here.